CONSULTATIVE APPROACH

Our consultative approach can help you in making your decision. We don’t issue a report on the way out only but take time to meet you and share our findings with providing recommendations based on our expertise and discuss how each action impacts your operations and the entire part of your business.

Our consultative approach can help you in making your decision. We don’t issue a report on the way out only but take time to meet you and share our findings with providing recommendations based on our expertise and discuss how each action impacts your operations and the entire part of your business.

Inspection and preventive maintenance consulting service consist of several keys notably:

Safety: to inform you of detected safety-related faults or issues before our expert leaves your site or before the equipment resumed operation.

Review & Recommendation: following the completion of every service request, our inspector will share the insights of the inspection or maintenance findings then review the identified risks and recommended actions either in written or/ and with your responsible staff if required.

ANALYSIS & RECOMMENDATION

Utilizing scientific potential and manpower of our specialized laboratory, we take a unique, consultative approach to crane maintenance and repair.

Utilizing scientific potential and manpower of our specialized laboratory, we take a unique, consultative approach to crane maintenance and repair.

Each component is inspected in situ without dismantling and disassembling where it is suitable and possible in order to ascertain its condition. Failures, deficiencies and violations are calculated, identified & documented. In addition, a variety of improvement opportunities can be defined. Recommended actions are determined, discussed and conformed with the Client to stay always on the safety side without any compromise.

INSPECTION & TEST

When you need an inspection to simply ascertain the condition of your equipment, we offer various inspection products based on the manufacturer’s recommendations, industry regulatory requirements where applicable as well as our laboratory’s experience and expertise.

Respective inspection and/ or test program will be developed and conformed with the Client in order to achieve the result following most effective, economic and safe way.

RETROFIT & REPAIR

Retrofit or/ and repair may be required to extend the service life of your cargo handling equipment (derrick, mobile crane, portainer (container crane), various warehouse cranes e.g. dockside crane, quay crane, gantry crane, deck crane, ship unloader and etc.) giving to an aged tool a new life. Also it would be a subject of increasing the speed and lifting capacity, application new safety measures and positioning capabilities, or simple replacement of obsolete components with modern ones. Everything you may need is a subject to negotiation and the search for solution to the issue basing to protect your investment. Once upgrade or repair successfully completed with our support and follow up you will eventually have integrated equipment that is tailored to your current operational requirements.

Retrofit or/ and repair may be required to extend the service life of your cargo handling equipment (derrick, mobile crane, portainer (container crane), various warehouse cranes e.g. dockside crane, quay crane, gantry crane, deck crane, ship unloader and etc.) giving to an aged tool a new life. Also it would be a subject of increasing the speed and lifting capacity, application new safety measures and positioning capabilities, or simple replacement of obsolete components with modern ones. Everything you may need is a subject to negotiation and the search for solution to the issue basing to protect your investment. Once upgrade or repair successfully completed with our support and follow up you will eventually have integrated equipment that is tailored to your current operational requirements.

RELIABILITY STUDY, STEEL STRUCTURE ANALYSIS

We provide detailed analysis of your cargo handling equipment in relationship to its application by evaluating the structural integrity of its construction and the condition of mechanical and electrical components as well as study load and duty requirements and maintenance records. When all information gathered and considered against the required performance needs, we will identify the most appropriate way for upgrade/ repair then develop and draw up respective project documentation.

ARRANGEMENT & SUPERVISION ON SITE

On construction sites large and small, supervision has a key role to play in preventing accidents. Typical supervisory functions include planning and allocating work, making decisions, monitoring performance and compliance, providing leadership and building teamwork, and ensuring workforce involvement. Supervision is therefore heavily involved in the running of a project and in particular in ensuring that health and safety is effectively managed. The level and nature of supervision required should be determined as an outcome of the client’s management arrangements for the project and from the risk assessments carried out by contractors and others. It is not sufficient to stipulate that “supervision will be provided” without specifying the detail of that provision. The client’s arrangements for managing the project and the risk assessments for the project should stipulate the level and nature of the supervision required. Questions such as who will supervise, how supervision will take place, how much is required and when need to be considered. Some workers and some activities will require more supervision than others. For example, young inexperienced workers may need very close and maybe constant supervision. Migrant or even local workers with poor English language skills or understanding of site safety standards, may need additional supervision. High-risk activities will need to be closely monitored by supervisors.

Our professionals are skilled and experienced in modernizations and repair, large and small. We have the expertise, technology and resources to modernize your cargo handling equipment.

OUR LABORATORY

Expertise and solution for a broad range of cargo lifting equipment

Head of the Specialized Laboratory:

Candidate of Engineering Sciences, Professor, Dean of the Port Engineering Department

The Specialized Laboratory team consists of:

- 1 Candidate of Engineering Sciences specializing in Vehicle Repair and Operation

- 2 Candidates of Engineering Sciences and 3 Masters specializing in Lifting Machines

- Team of welders (RMRS certified but the certification, which is needed for the certain country of project, is subject to be obtained)

Range of the Laboratory’s activities:

- Inspection of steel structures of lifting machines using visual, magnetic and ultrasound non-destructive methods;

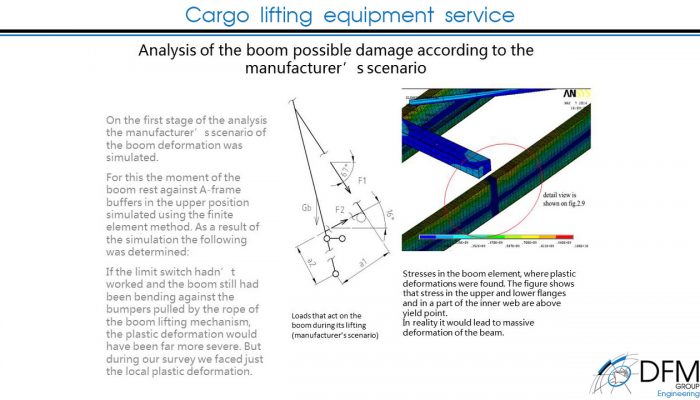

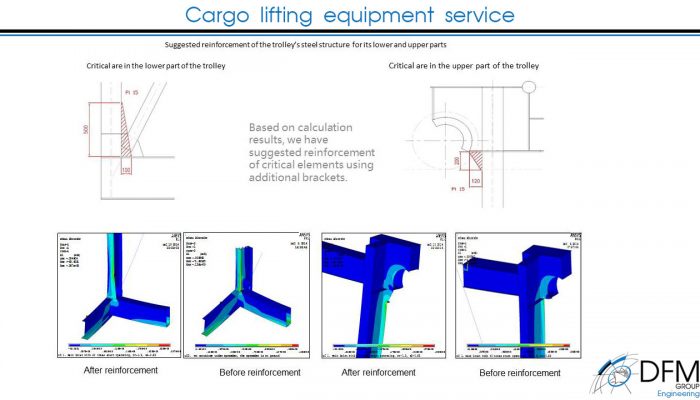

- Finite element method (FEM) calculations;

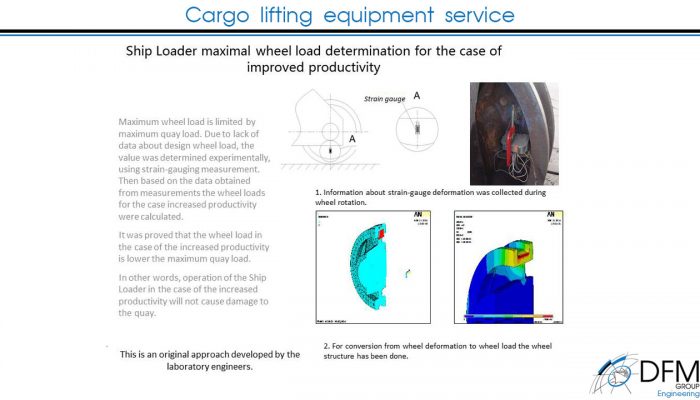

- Study of strain and stress measurement of steel structures;

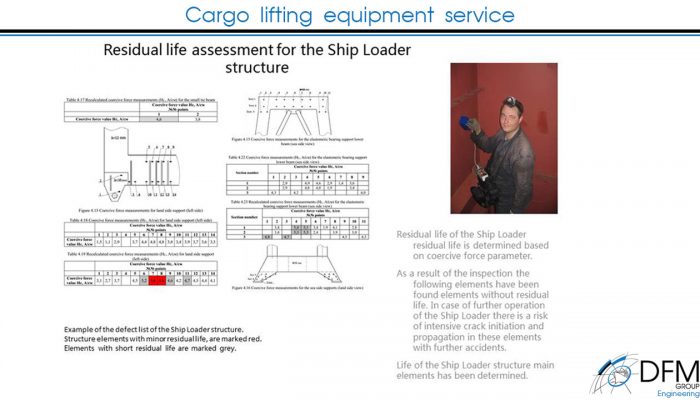

- Evaluation of remaining life (service period) of steel structure and components using coercive field strength Hc method and calculation based on FEM;

- Program development and testing of steel structures (impact resistance, tension, fatigue, etc.);

- Vibration analysis of machinery and steel structures – it allows to assess the condition of the equipment without its dismantling and thorough examination based on ISO standards’ (4866:2010; 10055:1996; 10816:2009 and etc.) principles.

- Development & drawing up repair and/ or upgrade documentation